Range Data

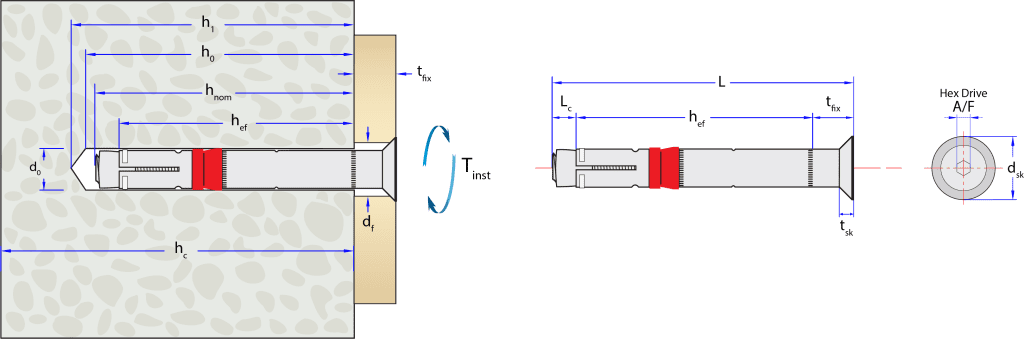

| Part Number |

Size of Thread

|

Min. Structure Thickness

(hc) mm

|

Drill Hole Diameter

(d0) mm

|

Min Hole Depth

(h1) mm

|

Fixture Clearance Hole

(df) mm

|

Cone Length

(Lc) mm

|

Effective Embedment Depth

(hef) mm

|

Max Fixture Thickness

(tfix) mm

|

Countersunk Thickness

(tsk) mm

|

Total Length

(L) mm

|

CSK Bolt Hexagon Drive

(A/F) mm

|

Countersunk Diameter

(dsk) mm

|

Tightening Torque

(Tinst) Nm

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLSK12/10SS | M8 | 120 | 12 | 80 | 14 | 11 | 60 | 10 | 5 | 80 | 5 | 20 | 17.5 |

| SLSK12/25SS | M8 | 120 | 12 | 80 | 14 | 11 | 60 | 25 | 5 | 95 | 5 | 20 | 17.5 |

| SLSK12/50SS | M8 | 120 | 12 | 80 | 14 | 11 | 60 | 50 | 5 | 120 | 5 | 20 | 17.5 |

| SLSK15/15SS | M10 | 140 | 15 | 95 | 17 | 14 | 71 | 15 | 5.7 | 100 | 6 | 25 | 42.5 |

| SLSK15/25SS | M10 | 140 | 15 | 95 | 17 | 14 | 71 | 25 | 5.7 | 110 | 6 | 25 | 42.5 |

| SLSK15/50SS | M10 | 140 | 15 | 95 | 17 | 14 | 71 | 50 | 5.7 | 135 | 6 | 25 | 42.5 |

| SLSK18/20SS | M12 | 160 | 18 | 105 | 20 | 16 | 80 | 20 | 6.7 | 115 | 7 | 30 | 50 |

| SLSK18/40SS | M12 | 160 | 18 | 105 | 20 | 16 | 80 | 40 | 6.7 | 135 | 7 | 30 | 50 |